ColdStream Energy (CSE) has developed a field proven, robust, and energy efficient gas separation technology for natural gas processing. This technology operates independent of process temperature or ambient temperature and is designed for unattended operations to be remotely controlled or monitored. It is a simple and economically compelling solution for maximizing NGL value for producers and gatherers, while also maximizing the efficiency and runtime of engines and respective compressors. The ability to produce pipeline quality, < 1,100 BTU/scf (HHV), lean gas at any location ensures the lowest VOC emissions possible, even when remotely located. This is an innovative and valuable technology for the energy industry with wide applicability, and especially relevant to gas gathering and compression stations.

The advantages of the MaCH4™ NGL Recovery Solution technology to other natural gas separation technologies are:

- Simple process for unattended operations that can be remotely monitored and controlled

- Low maintenance with minimal operator intervention, over 99% mechanical availability

- Large 10:1 turndown ratio

- Handles BTU swings from fluctuating feed gas compositions

- Cryogenic-like recovery of NGLs without the low temperature requirements (no freeze issues)

- Minimal power requirements (single phase), especially compared to cryogenic processes

- Recovered heavy hydrocarbons remain in gaseous form (no liquids, no product storage tanks required)

- Requires no chemical consumables to operate (i.e. methanol, glycol, lubricating oil)

- Skid mounted and field transportable

- Dehydrates the saturated feed gas and recovers heavy hydrocarbons in a single step process

What is the Feed Gas (FG) supplied to MaCH4?

The MaCH4 feed gas is the slipstream of the compressed field gas from the gathering station discharge header, compressor 2nd stage discharge, or compressor 3rd stage discharge that will be separated into a light and heavy product.

What is Gas Separation and how does it differ from Gas Processing?

Gas Separation is a specific step within the larger gas processing workflow. It involves physically or chemically isolating various components of a raw gas stream, such as methane, ethane, propane, butanes, and natural gas liquids (NGLs), to generate a distinct stream of heavy hydrocarbons for downstream processing and monetization. This separation typically targets bulk removal of water, condensates, and impurities using methods like mechanical separation, adsorption, or other techniques.

Gas Processing, however, is a broader and more stringent operation aimed at refining the gas stream to meet very specific commercial, safety, and regulatory quality specifications. It includes not only gas separation but also advanced treatment steps such as dehydration (removing trace water), sweetening (removing acid gases like H₂S and CO₂), fractionation (breaking down NGLs into pure individual components), and compression. The goal of gas processing is to deliver gas products that comply with strict pipeline, sales, or fuel gas specifications, ensuring consistent purity, calorific value, and safety.

In summary, Gas Separation focuses on separating the main components from raw gas, while Gas Processing encompasses the full, precise refinement process needed to produce market-ready gas products that meet stringent quality requirements.

What are the differences between Field Gas Conditioning and Fuel Gas Conditioning?

Field Gas Conditioning refers to the treatment of raw gas directly at the wellsite or production facility. Its primary purpose is to remove contaminants such as liquids, solids, and corrosive components (like water, hydrogen sulfide, and CO₂) to make the gas suitable for transportation via pipelines or for further processing. This step ensures that the gas meets quality and safety standards before it enters the midstream or downstream systems.

Fuel Gas Conditioning, on the other hand, is focused specifically on preparing gas that will be used as fuel onsite, typically in engines, turbines, or heaters. The goal here is to ensure that the fuel gas is clean, dry, and free of impurities that could damage equipment, reduce efficiency, or cause emissions problems. This process often involves removing liquids, particulates, and contaminants to protect fuel system components and comply with operational requirements.

In summary, Field Gas Conditioning prepares raw gas for transport or processing, while Fuel Gas Conditioning tailors the gas quality for safe and efficient use as fuel in onsite equipment.

What is the Light Product (LP) produced by MaCH4?

The light product produced by MaCH4 is the dehydrated, lean fuel gas that feeds an engine or engine fuel gas header for distribution to multiple engines at a gathering station.

What is the Heavy Product (HP) separated by MaCH4?

The heavy product separated by MaCH4 are the heavy hydrocarbons (NGL’s) recovered as gaseous vapors and sent back to the compressor suction or suction header.

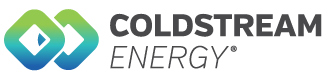

What is Pressure Swing Adsorption (PSA)?

The concept of PSA for gas separation is relatively simple. When a gas mixture is introduced to an adsorbent, certain gases in the mixture selectively adhere onto the adsorbent surface. Each PSA system uses specialized adsorbent materials to capture the target gas species at high pressure, while all other gases in the mixture pass through the adsorbent bed. The process then swings to low pressure to desorb the captured gases, hence the name pressure swing adsorption. The desorbed gases are enriched with the more strongly adsorbed components of the feed gas. No external heat is needed for the regeneration of the adsorbent, making this a more energy efficient separation than traditional absorbent based technologies. As this is a regenerative process, none of the adsorbent material used is consumed.

CSE has adapted PSA for the novel use case of hydrocarbon gas separation. This means extremely high recovery of C3+ hydrocarbons for monetization rather than combustion, which also means a much-reduced VOC emissions profile due to combustion if one were to use this PSA produced lean, light product as fuel gas.

Joule-Thomson (JT) vs Adsorption

The Joule Thomson (JT) effect describes the temperature change of a gas when it is expanding, typically due to pressure loss from flow through a valve. This rapid pressure change and subsequent cooling of the gas often is used to condense heavier natural gas liquids (NGLs) from a natural gas stream. Additionally, natural gas has some water remaining in it, and this water content tends to freeze when the gas rapidly expands through a valve. This cooling occurs because work must be done to overcome the long-range attraction between the gas molecules as they move farther apart or expand.

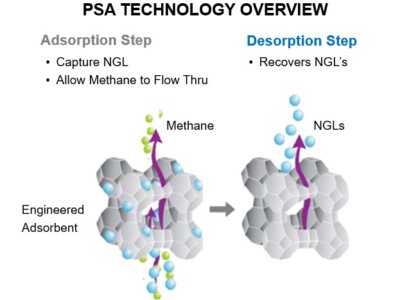

Adsorption is the adhesion of molecules from a gas to a surface. This process creates a film of molecules on the surface of the adsorbent. This process differs from absorption, in which a substance (the absorbate) is dissolved by or enters the volume of another (the absorbent), typically a liquid.

Adsorption physically separates gases based on the differing affinities or attraction for an adsorbent material under varying pressure levels. While gas molecules adhere (adsorb) to the surface of the solid adsorbent at high pressure and are then released (desorbed) at low pressure, the goal is the removal of these gaseous components from a mixture, not the condensation or liquefaction of the molecules.

Once the adsorbent surface is saturated with the captured/attracted gas molecules, the pressure is reduced, which causes the trapped gas molecules to desorb and be released. This is fundamentally a gas separation phenomenon. The separation mechanism is based on how strongly different gases adhere to the adsorbent’s surface, not on a phase change from gas to liquid. A change in pressure, changes the affinity of the molecules captured on the adsorbent (desorption). This does not cause a rapid expansion of the molecules.

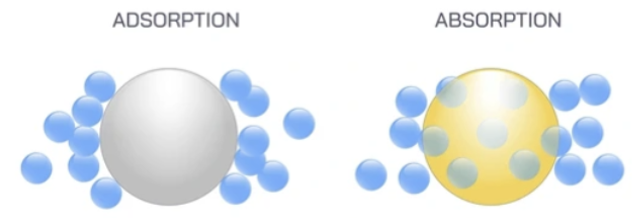

What type of lean gas or fuel gas quality can be expected from the PSA technology?

CSE’s PSA technology is truly versatile. Using this patented technology, CSE can produce any methane purity or fuel gas quality that a customer would like to specify. In a stepwise manner, the methane purity of the lean gas produced can be tuned from 1,000 BTU/scf (HHV) (98% C1) to 1,200 BTU/scf (HHV) (82% C1) and then back to 1,080 BTU/scf (HHV) (89% C1).

This flexibility and ability to produce a lean gas product consistently, at different BTU set points, is independent of process temperature or ambient temperature. All the lean gas set-points and product tuning can be done remotely. This ability to tune BTU content for the lean gas product also means the process is able to produce a consistent and desirable BTU value of lean gas even if the feed gas BTU changes over time. Tuning could also be desirable if one wanted to leave more ethane in the lean gas product rather than recover more ethane in the heavy hydrocarbon product.

This is cryogenic-like methane purity without the cost, complexity and footprint of a cryogenic process (see figure below).

How reliable is the system?

The Pilot was commissioned in December of 2023 and the process has consistently been producing desired fuel gas quality. The Pilot has had over 99% mechanical availability since commissioning with unattended operations, remote monitoring, and remote tuning since May 2024.

What connections are needed for this gas processing technology?

ColdStream Energy’s MaCH4 requires three (3) primary pipe connections: (1) high-pressure feed gas, either from discharge header, 2nd stage or 3rd stage discharge of a compressor; (2) light product fuel gas outlet, connecting to engine or engine fuel gas header; and (3) heavy product outlet, which takes the recovered heavy hydrocarbons (NGL’s) as gaseous vapors back to compressor suction or suction header (see figure below).

High pressure, high BTU gas enters the inlet of the MaCH4 and passes through pre-filters that remove any entrained lube oil in the gas. This high BTU gas then flows into the adsorption beds. Predominantly, the heavier hydrocarbons are adsorbed in the adsorbent beds and methane enriched gas passes through the beds into the buffer tank of the MaCH4 or directly into the engine or engine fuel gas header. The MaCH4 skid requires just minimal connections* and 1 single-phase electrical connection; System takes gas from final stage of compression and uses the discharge heat in the process (see figure below).

What are the utility requirements for the MaCH4?

The MaCH4 does not require fuel gas. Electricity service (2 x 120 VAC, 20 amp) is required for PLC control and remote operation, monitoring, and powering on-skid heat trace circuits. Additionally, dry instrument air or gas, and high-pressure drain line are required.

Who operates the technology?

The MaCH4 is designed to operate unattended. The MaCH4 control system has the capability of remote start per a preprogrammed process or may be initiated by an on-site / or remote operator. Either ColdStream Energy (or its distributor) or the customer will conduct check-ins of the unit. Operational adjustments will be made as required remotely.

Do you offer a leasing option?

Yes, the MaCH4 NGL Recovery Solution is available for direct purchase or lease. Contact us for more details.

What happens when the MaCH4 shuts down?

When there is an operator initiated normal shutdown of the MaCH4, the unit will shut down per a preprogramed procedure. For an ESD, the MaCH4 immediately shuts down and the MaCH4 outlet ESD valves are shut. The MaCH4 is programmed to ready itself for a restart of the PSA process, once start up procedure is initiated or ESD notification is cleared.

What happens when customer’s compressors shut down?

For black start, feed gas will be supplied from a discharge header. It is assumed that there will not be operating compression on location during start up but there will be high pressure gas for the PSA process downstream of compression at the discharge header. Discharge flow control valve (FCV) is set fully open at start-up.

At what pressure does the MaCH4 provide lean product fuel gas?

The MaCH4 can provide lean product fuel gas to the customer at supply pressures below 150 PSIG but can be modified to even higher lean product fuel gas supply pressure at customer’s request.

Will fluid slugs be a concern to the system?

The MaCH4 receives high pressure gas from the high-pressure discharge post-scrubber, removing most fluids prior to PSA process inlet. There is also a filter coalescer to remove lube oil and other fine fluid droplets upstream of the PSA process.

Post processing, the MaCH4 recycles the heavy product to the compressor station suction header or a low-pressure gas gathering line. The heavy product will remain a vapor up to and after recycling to the station suction header. ColdStream will provide a process simulation of the flows and composition of gas from suction through discharge of the compressor.

Will I need a pressurized tank to store NGLs?

No NGL tanks are required. Heavy product (NGL’s) are separated as gaseous vapors in the CSE process for monetization downstream.

What chemicals are used in the MaCH4?

The chemicals in the MaCH4 include the adsorbent (a novel proprietary nanomaterial) which is non-toxic and contained in the adsorber vessels. This nano-adsorbent will contain residual hydrocarbons if removed from the adsorber. There are no special requirements for disposal of the adsorbent except for the residual hydrocarbon. Safety Data Sheets (SDS) can be provided for the adsorbents.

No other chemicals are used or consumed in this process.

Will contaminants in the gas such as lube oil impact PSA performance?

A filter coalescer is upstream of the PSA process and will remove entrained lube oil in the gas prior to processing.

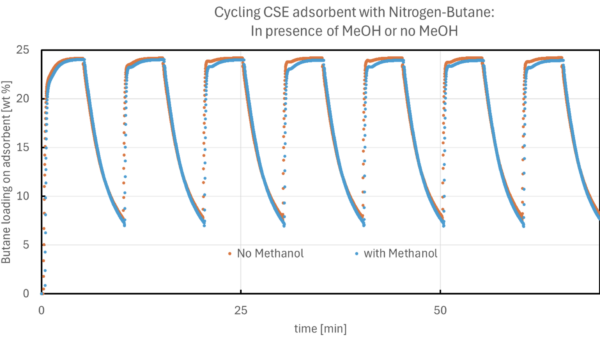

Will contaminants in the gas such as methanol impact PSA performance?

Methanol is often used in the oil field to prevent hydrate formation. However, it is liquid at the operating pressures and temperatures of the CSE process and will be removed by the filter coalescer.

Read more about Methanol physical properties: https://www.engineeringtoolbox.com/methanol-methyl-alcohol-properties-CH3OH-d_2031.html

Data shows that there is no impact to hydrocarbon capture by the adsorbent in the presence of methanol.

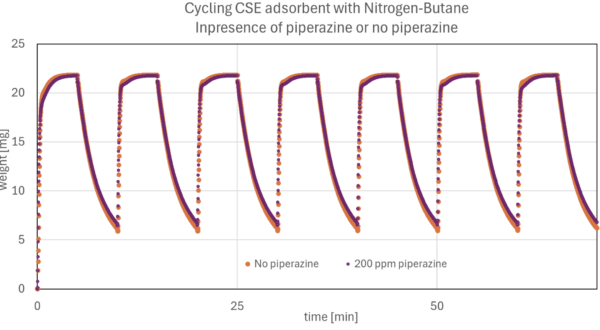

Will contaminants in the gas such as piperazine impact PSA performance?

Piperazine is an amine used in the oil field for acid gas removal purposes in small mol% concentrations. It has a melting point of 223 °F (106 °C) and will be a solid at the operating pressures and temperatures of the CSE process. If this solid amine is not removed by pre-treatment upstream of the CSE process, it will have no impact on the hydrocarbon separation process.

There has not been any documented evidence of piperazine interacting with hydrocarbons or it would not have been chosen as a chemical for the more traditional acid gas treatment processes.

Read More: Piperazine on Wikipedia

Data shows that there is no impact to hydrocarbon capture by the adsorbent in the presence of low-level concentrations of piperazine.

What is the life of the adsorbent?

The adsorbent life is expected to be between 5 to 7 years. This will be dependent on the level of contamination of the source gas that may bind irrevocably and the pre-treatment upstream of the CSE process to remove aforementioned contaminants.

If the adsorbent has been determined by CSE to have reached the end of its “useful” life, CSE will schedule an adsorbent changeout for the MaCH4. There are no special requirements for disposal of the nano-adsorbent except for the residual hydrocarbon and other potential contaminants traditionally found within raw gas. Changeout should take approximately one day to safely remove and then replace the adsorbent. The process should be able to re-start as soon as the adsorbent is replaced, the system is fully purged, and all system start-up checks passed.

How soon after startup is 1,070 BTU (HHV) reached for the fuel gas?

High quality lean product is produced very quickly after process operating pressure is achieved and introduced into the system. Once field gas is introduced to the adsorbent, the heavier hydrocarbons are removed from this gas as it flows past the adsorbent. The desired lean product is what exits the process, as diagramed in our technology overview diagram.

What moisture content of the field gas is acceptable?

The CSE process can accept water saturated field gas at inlet, because the process is designed to remove both heavy hydrocarbons and water vapor from the field gas simultaneously to produce a lean, dry gas product that will meet pipeline specifications.

Does the feed or field gas need to be dehydrated?

The feed or field gas does not need to be dehydrated. The CSE process will help dehydrate the feed or field gas.

How does the MaCH4 solution help reduce emissions?

Volatile Organic Compounds (VOCs) known as Hazardous Air Pollutants (HAP’s) and Carbon Dioxide (CO2) are greatly reduced from combustion emissions because MaCH4 is removing the C3+ hydrocarbons from feed gas with CSE’s proprietary process prior to combustion. CSE’s process to lower VOC emissions can help add compression at a constrained gathering station to stay out of Title V, reduce emissions for existing Title V facilities, extend catalyst life, or reduce the number of catalysts required to meet air permitting requirements.

Is there a concern of fugitive emissions with this process technology?

No. All valves within the MaCH4 are instrument air actuated, not field gas actuated. All valves used by CSE will have passed API Standard 598 as per valve manufacturer certifications.

Once installed on site, the MaCH4 will also be part of a facility’s LDAR program. Additionally, as part of routine maintenance of the MaCH4, CSE will also test the valves for leakage under API 598 protocols.

Can the system be remotely operated?

Yes. CSE technology can be remotely monitored and operated.

What is the turn down capability?

The MaCH4 can operate efficiently at significantly reduced flow, up to a turndown ratio of 10:1. Flowrate into the system is controlled by an operator adjustable inlet flow control valve to the system. In case of sudden changes in product demand, there is a pressure regulator built into the system that will safely redirect any excess lean product back to the compressor suction or suction header.

How stable is the light product fuel gas BTU value with changing feed or field gas BTU value?

The CSE process can manage lean gas product BTU value even with a changing field gas value of over 60 BTU HHV value on a day-to-day basis.

When a wider deviation or change of raw gas BTU from initial design is anticipated from the customer, CSE can remotely adjust parameters to ensure desired lean gas product quality is met. The MaCH4 system has an on-skid gas chromatograph (GC) that continuously monitors both feed and product conditions to ensure product quality will always be maintained.